Why Manufacturers Should Outsource Their Purchasing

Manufacturing companies often need to continually optimize their operations for efficiency and cost-effectiveness. A strategy that is gaining popularity among manufacturers is to outsource their purchasing services. This not only allows businesses to streamline their processes but also opens the door to a myriad of benefits.

In this article, we explore four compelling reasons why manufacturers should consider outsourcing their purchasing activities to Echelon Supply Chain Solutions.

Indirect Labor Cost Savings Up to 50%

Outsourcing purchasing services allows manufacturers to leverage external resources to minimize the need for full-time staff. What's more is that outside purchasing services are paid by the transaction so that buying functions now become a variable cost rather than fixed. Additional payroll and overhead expenses are also avoided. This financial flexibility enables companies to allocate resources strategically, investing in core business areas to foster overall growth.

Add Specialized Expertise

In addition to tactical purchasing, Echelon Supply Chain Solutions can also provide manufacturers with deep expertise in Materials Requirements Planning (MRP), data management, engineering change management, demand planning/SIOP, and inventory optimization. This augmentation enhances the efficiency and precision of procurement processes, leading to improved decision-making and a more streamlined supply chain.

We are often able to reduce raw material or finished good inventories by 20% to 40% while still ensuring service levels of up to 100%. Our proprietary inventory optimization methods allow us to effectively formulate a buying strategy for each item that accounts for supplier performance, customer dynamics, forecasts, and other factors.

MRP Data Clean Up and Optimization

Outsourcing provides an opportunity for MRP data clean up and optimization, ensuring that the foundation of your procurement process is robust and reliable. Our experts can assess and remediate your MRP data, identifying and rectifying inconsistencies or inefficiencies. This proactive approach enhances the accuracy of demand forecasting and inventory management, reducing the risk of shortages or overstock.

Reallocate Procurement Responsibilities for Strategic Focus

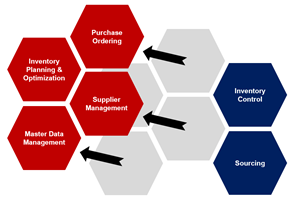

Outsourced purchasing services allow manufacturers to reallocate their internal procurement responsibilities, freeing up valuable time and resources. With routine procurement tasks handled externally, in-house teams can shift their focus to more strategic areas such as sourcing and inventory control. This strategic reallocation empowers businesses to maximally utilize resources to strengthen supplier relationships, exercise cost control, and actively improve inventory accuracy.

Bottom-Line Improvement

Outsourced purchasing emerges as a strategic opportunity for manufacturers to reduce costs, enhance operational efficiency, and refocus internal resources on strategic initiatives. This can position your business for sustained growth and competitiveness in an ever-evolving market landscape.